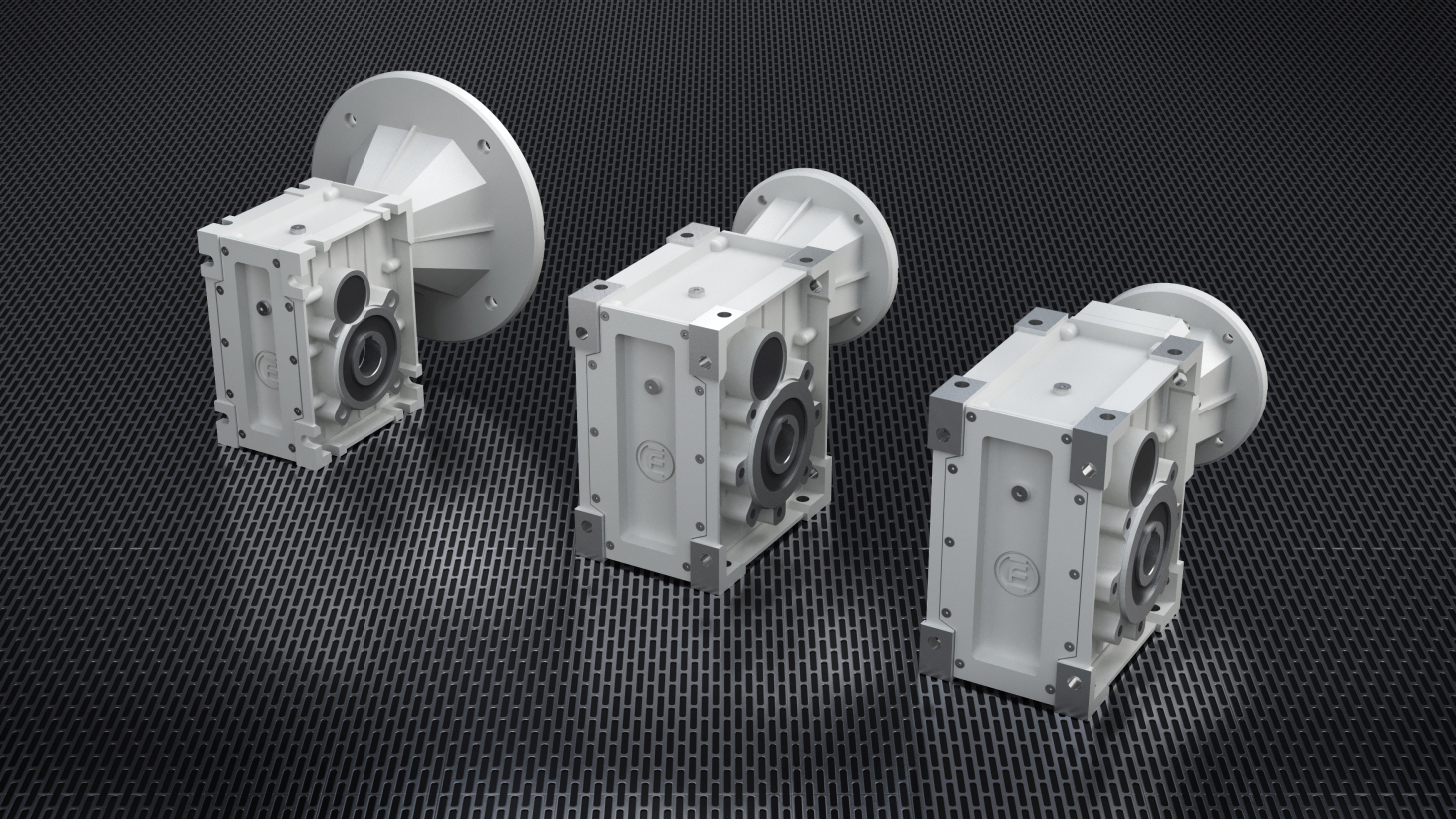

THF Geared motors

THF gearboxes are a new drive design with bevel wheels whose axes are hypoidly shifted relative to each other. They belong to the ALU-G Motion™ series. THF gearboxes are an ideal replacement for energy-inefficient worm gears, therefore they have a real impact on improving the energy balance of modern working machines, including transport machines.

In a powertrain, replacing a low-efficiency motor with one with a higher efficiency motor can only marginally improve energy efficiency if an inefficient worm gear is left behind. Replacing the worm gear with a THF hypoid gear will improve the energy balance of such a drive system without additional assembly costs.

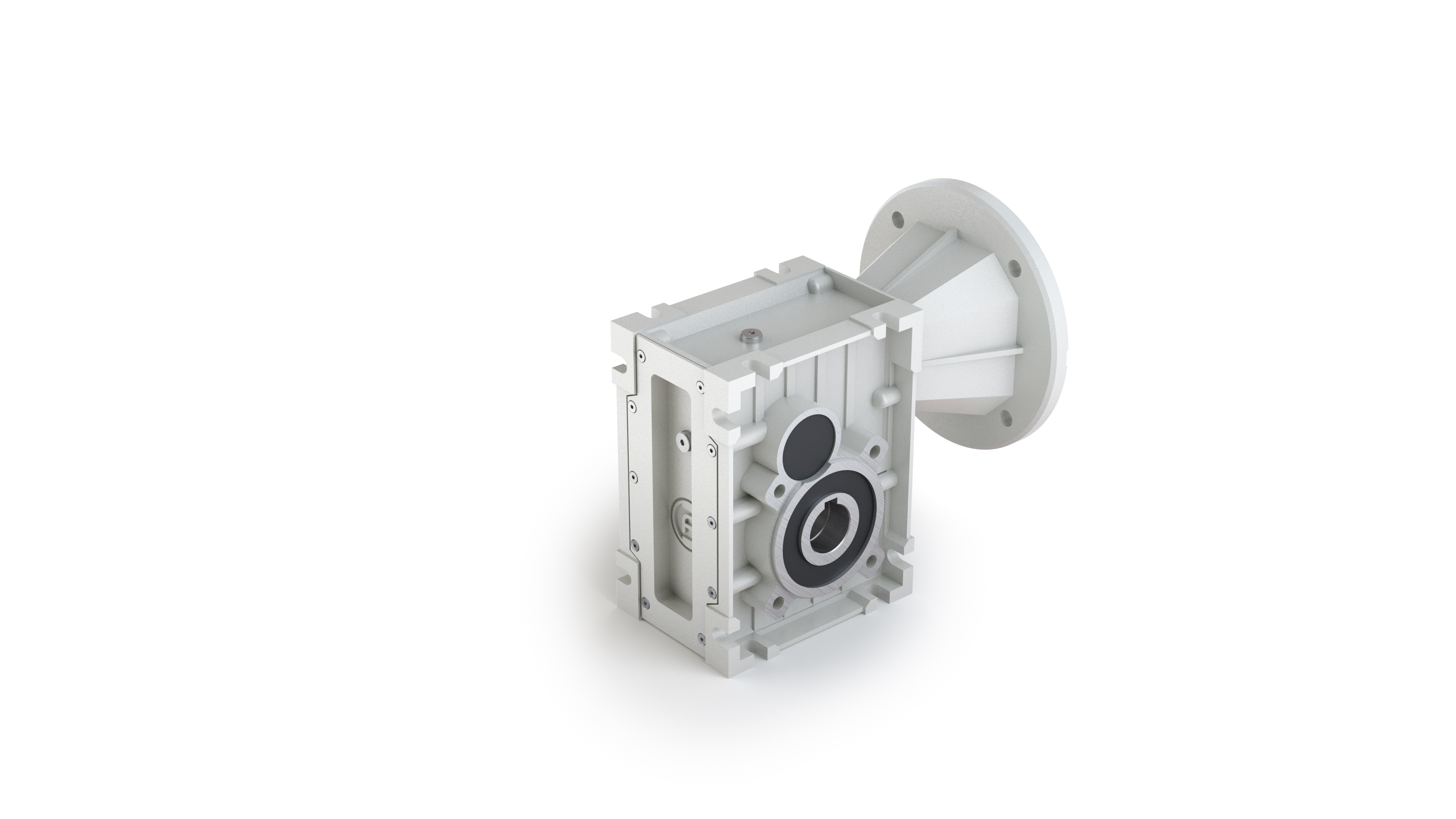

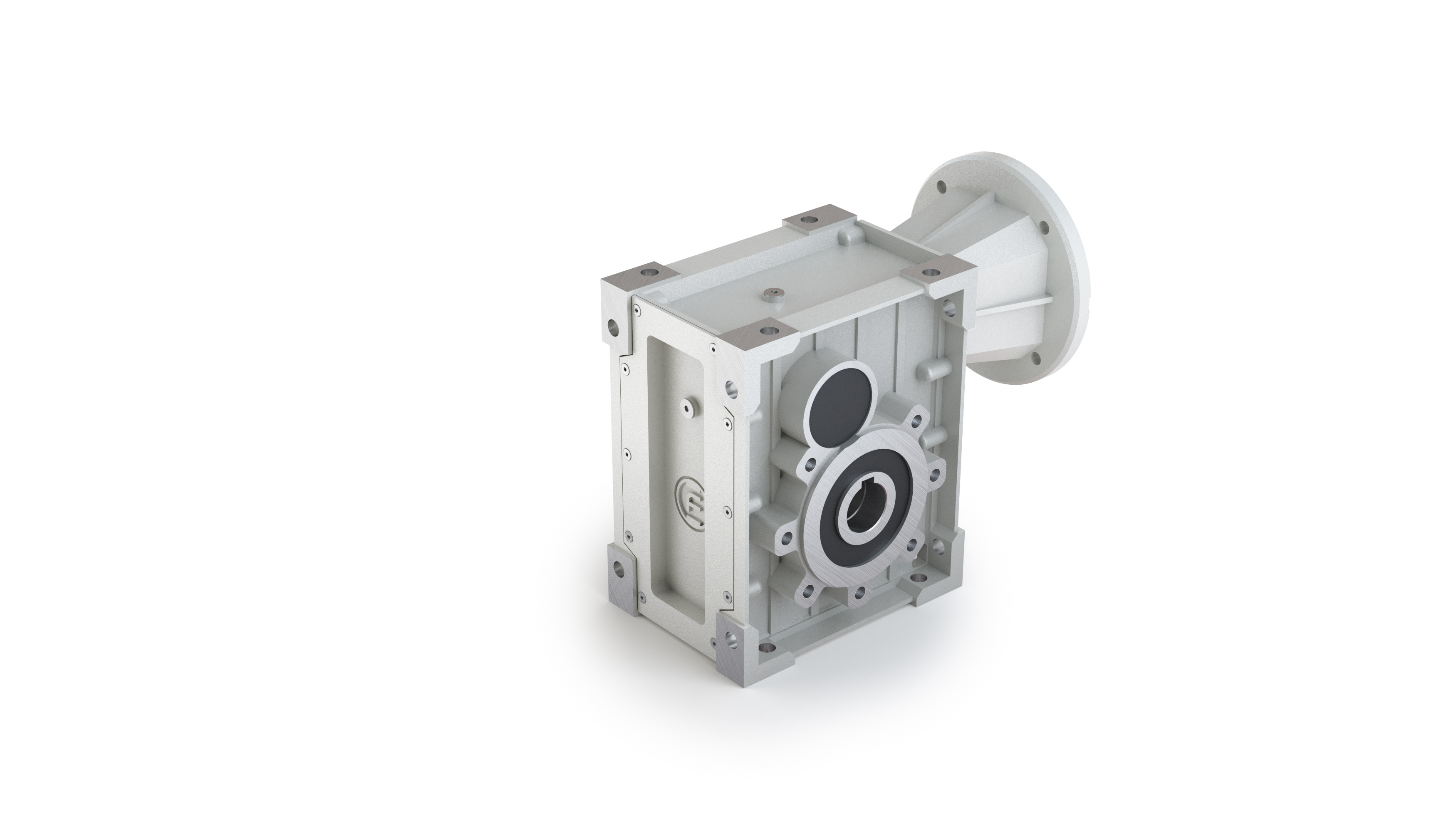

Higher load capacity - than a bevel gearbox with the same overall dimensions, thanks to the extension of the active length of the tooth.

Higher output torque - than in worm gears of the same mechanical size and ratio.

Warranty - the products are under our warranty, we also provide post-warranty services.

Technical parameters - four mechanical quantities with two gear ratios and four mechanical quantities with three gear ratios provide a torque range from 5 Nm to 500 Nm in the range of available gears from i=7.73 to i=297.21

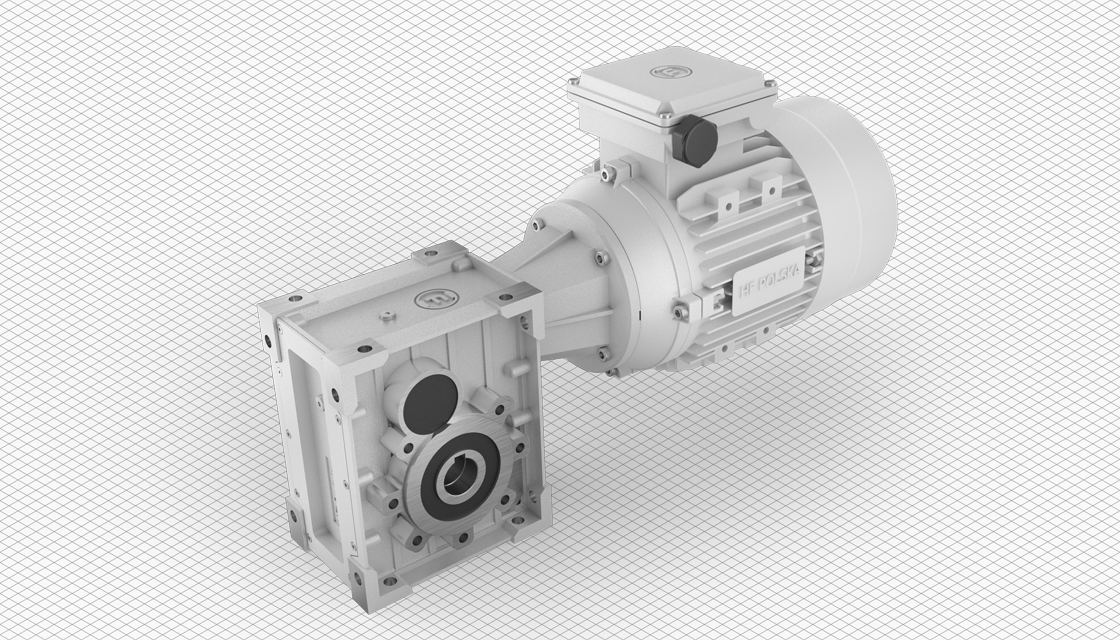

Quick assembly - without mechanical modifications, a THF gearbox can be mounted in place of a worm gear with sizes 050, 063, 075 and 090.

"The use of a THF hypoid gear instead of a worm gear will improve the energy balance of the drive train and the working machine.

THF hypoid gears have twisted gear axles, just like bevel gears. The design of the THF hypoid gear differs from the design of the bevel gear by the transverse displacement of the pinion axis (hypoid shift) in relation to the axis of the disc wheel. Thanks to the hypoidal shift, an extension of the active length of the teeth is achieved, which affects the strength and load capacity of the THF transmission. The efficiency of the hypoid gear is inversely proportional to the hypoid shift and decreases with its increase. The efficacy of THF gears falls within the range of 88% to 92% and depends on the switch. The gears are made of chromium-manganese alloy structural steel with the addition of titanium 20CrMnTiH1, which works well in parts of machines heavily loaded and exposed to impact forces. The gear bodies are made of high-quality cast aluminum, additionally covered with a varnish coating. Seals are made of high quality materials such as NBR (acrylic butadiene rubber). These and other technical features make the THF transmission a reliable drive. THF geared motors also meet the high demands placed on drives in terms of output speed and low curb weight.

-

12 December 202326.54 MB541 downloads

-

09 September 20224.14 MB866 downloads

-

09 September 20223.05 MB685 downloads

-

15 February 2022512 KB1069 downloads