Frequency inverter E-600

EURA E-600 frequency inverters are characterized by modern, small and compact design. It is designed for simple and undemanding applications such as fan drives, pumps and belt conveyors.

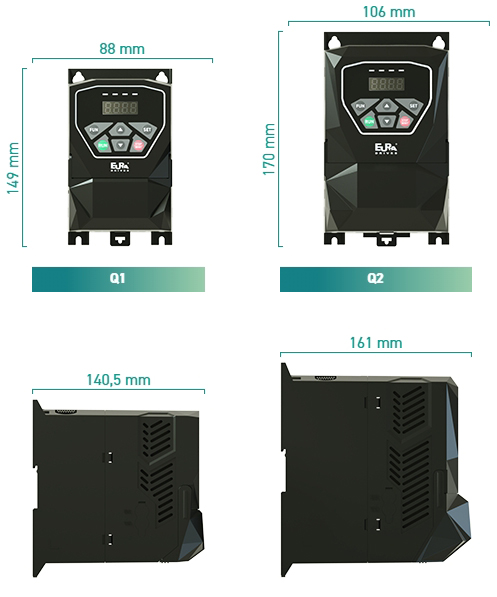

Despite its small dimensions and simplified to the maximum operation, the E-600 is suitable for applications where it is important not only to control the operation of the motor, but also to save electricity. Built-in EMC filter, PID controller and ModBus communication enable this frequency inverter to be used in various industrial applications. The housing has been optimized for easy and quick mounting on a DIN rail or directly on the mounting plate in the control cabinet.

EURA E-600 frequency inverters have IE2 efficiency class and comply with Commission Regulation (EU) 2019/1781 defining ecodesign requirements for electric motors and infinitely variable speed control systems under Directive 2009/125/EC

Reliable and user-friendly - the E-600 frequency inverter is based on the same parameterization scheme of the device as is used in other models of EURA drives.

Compact drive - despite its small dimensions and simplified to the maximum operation, the E-600 is suitable for demanding applications.

Network Protection - Built-in EMC filter effectively reduces interference.

Easy operation - backup capability thanks to cooperation with free EuraDV™ software and EURA CopyStick™ peripheral.

Universal application - built-in PID controller and ModBus communication enable the use of the E-600 drive in various industrial applications.

Quick installation - housing optimized for easy and quick mounting on a DIN rail or directly on the mounting plate in the control cabinet.

"Reliable and user-friendly - the EURA E-600 frequency inverter is based on the same parameterization scheme of the device as is used in our other models.

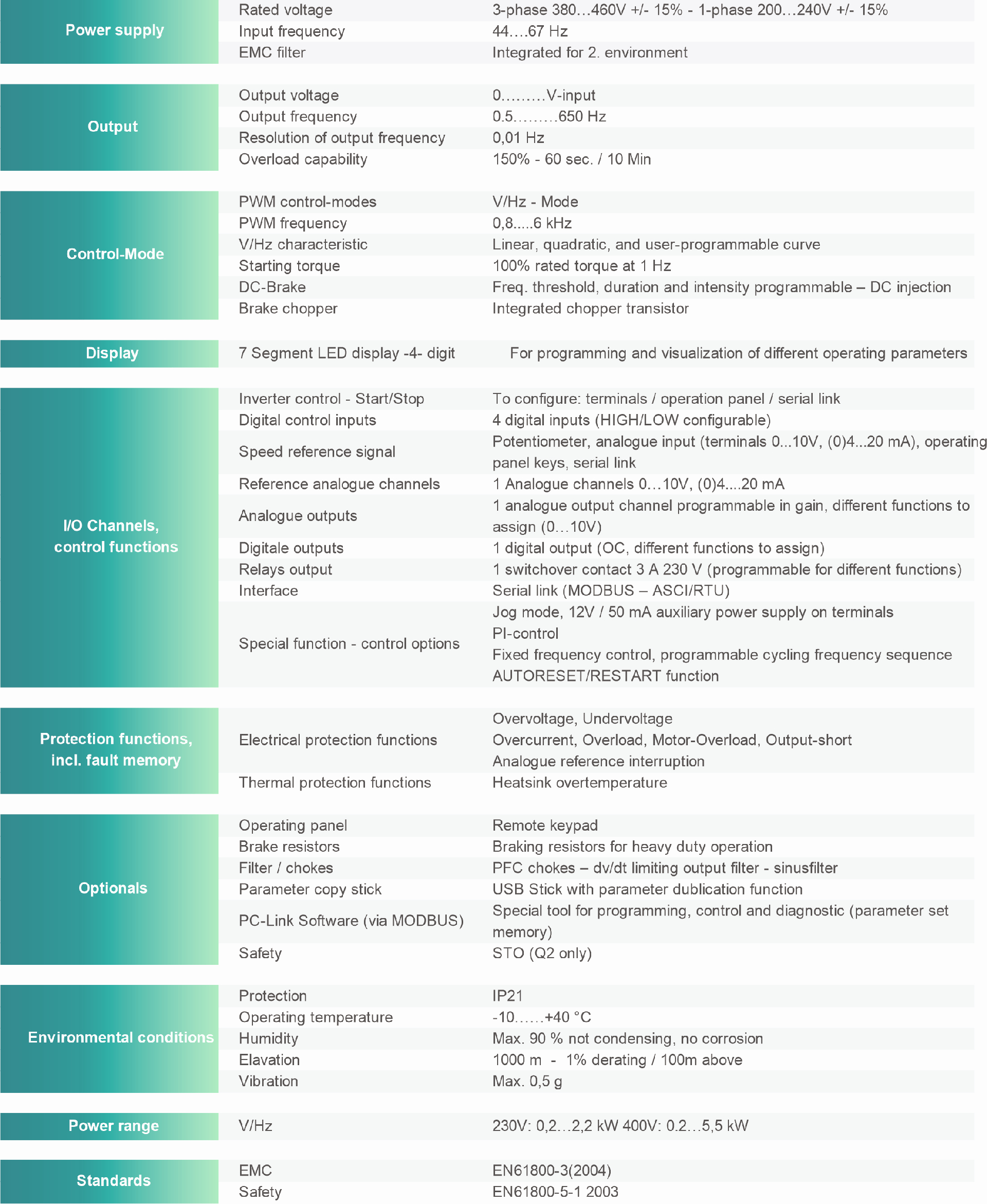

The basic type of control of the EURA E-600 frequency inverter is the VVVF (Variable Voltage Variable Frequency) scalar control in which the linear characteristic of the U/f curve or the square characteristic U/f can be set, and the user-defined characteristics are also available. The drive has automatic or freely defined torque gain in the range of up to 20 curves, and it is worth mentioning that the initial torque is 100% already at a frequency of 1.00Hz! The precision of motor control is achieved with high resolution of the frequency setting - for digital defining it is 0.01Hz and for analog it is the quotient max. frequency x 0.2%. There are two types of the launch of power system - direct launch without a volatile start (without control of the current engine speed) or a volatile launch. Multi-speed operation allows the user to set up to 15 constant speeds on digital inputs. You can also program automatic work up to 8 steps. For optimal control of the electric motor, you can define the carrier frequency (keying) in the range from 0.8kHz to 6.0kHz or set the converter to automatically set this parameter depending on the operating conditions of the motor.

-

24 August 20221.18 MB1059 downloads

-

24 August 20221.28 MB784 downloads

-

24 August 20222.78 MB772 downloads

-

14 February 2022639 KB856 downloads